Tirada Dalbashada Ugu Yar:100 kiiloomitir

Faahfaahinta Baakadaha:

Xidhmada A: 20kg/ Foosto Bir ah

Xidhmada B:20KG Foosto Caaga ah

Xidhmada C: Iyada oo ku saleysan qadarka wakiilka B

Waqtiga dirida:Toban maalmood ka dib markii la helo lacag hormaris ah

Shuruudaha Lacag-bixinta:L/C, T/T

Awood-siinta:2 Tan/Tan maalintii

Midabka:Silver

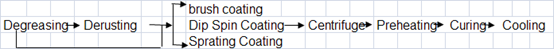

Habka Dahaarka:Dahaarka Quus oo Buufi

PH (20 ℃):5.0-8.0

Cuf-jiid gaar ah:1.30-1.40 (Daahan buufin)

Viscosity:Marka loo eego Baahida Hawlgelinta

Heerkulka shaqada:22± 2℃

Sharaxaada

JH-9610 waxa uu ka kooban yahay saddex baakidh: A,B iyo C;

Xidhmada A: Waa slurry qalin qalin ah oo inta badan kiimikaad lagu daray flake aad u fiican oo Zn ah, flake aad u fiican oo Al ah iyo wax lagu daro organic.

Xirmada B: Waa xalka biyaha oo inta badan lagu daro wax lagu daro ilaalinta daxalka, xalinta biyaha gaarka ah iwm.

Xirmada C: Waa takitarka dahaarka kaas oo inta badan ka kooban budo jaalle ah ama cellulose.

Tilmaamaha Waxqabadka:

1. Chrome bilaash ah;

2. Waxqabadka dusha sare ee wanaagsan, ka-hortagga-daxalka sare, isku-dhafka hooseeya;

3. Ma jiro burburka hydrogen, ma jiro hab wax lagu soo qaado;

4. Iska caabbinta kulaylka wanaagsan;

5. Saacadaha SST ee wanaagsan, wareegga gabowga waa dheer yahay, wuxuu dabooli karaa alaabooyin badan oo hoos yimaada shuruudaha habka isku midka ah.

Habka dahaarka

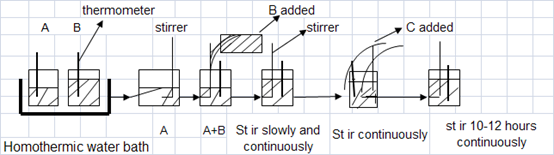

1. Isku qas Saamiga

Xidhmada A: Xidhmada B: Xidhmada C=1:1: X(sida ku xidhan baahida viscosity ee kala duwan)

2. Kahor Isku darka, Ku hay Miisaanka A&B qubayska biyaha at 25± 2℃, ka dibna walaaq A si aad u samayso slurry biraha si isku mid ah u kala firdhiso isku-darka inta jeer, ka dib markii A si buuxda loo kala firdhiyo, yaree xawaaraha kacsan ilaa 60r / min, oo ku dar B .

3. Ku dar B si tartiib ah u walaaqaya.

4. Ku walaaq isku dar ah ilaa 1 ~ 2 saacadood ka dib marka lagu daro B, ka dibna ku dar C. C waa in la buriyo haddii buro jirto. ~ 12 saacadood si tartiib ah oo joogto ah.

Isku qas jaantuska

Fiiro gaar ah

1. Kiimikooyinka kale sida nooc kasta oo aysiidh ah, milix alkali ah laguma qasi karo daahan, waayo kuwani waxay dhaqaajin karaan Zn & Al plate si ay u gaboobaan dahaarka.

2. Iska ilaali shucaaca qoraxda iyo raajada ultraviolet muddo dheer markaad shaqaynayso, haddii kale waxay dedejin doontaa gabowga ama polymerization ee dahaarka .

3. Aad bay muhiim u tahay in la xakameeyo heerkulka daahan.Haddii heerkulka daahan uu isbedelo marka hawlgalka, waxay saamayn doontaa viscosity ah, ka dibna saamayn tirada daahan on workpiece.Markaa xidhiidhka ka dhexeeya heerkulka, viscosity iyo habka wareegga waa in si fiican loo xakameeyo marka la dahaadho.

4. Viscosity-ku wuu ka duwanaan doonaa haddii habka dahaarka uu ka duwan yahay.Dooro xog hoose haddii daahan la buufiyo, oo dooro xog sare haddii dahaarka isbidayga la gashado.

Xogta Farsamada

| Maya | Shayga | Xogta |

| 1 | Midabka | Silver |

| 2 | Habka dahaarka | Qudhsiinta & buufinta |

| 3 | PH | 4.8-7.5 |

| 4 | Cuf-jiid gaar ah | 1.45 ± 0.1 (Dahab buufin) |

| 5 | Viscosity | 25 ~ 40s (Dahab buufin) |